Interviewed by Viet Trademark magazine on June 2010

Occasion of the New Toyo ( Viet Nam) Aluminuim Paper Packaging Co., Ltd received “Sustainable Green Brand Award 2010” in June 04, 2010. Viet Trademark Magazine reporter have interviewed Ms Nhan Huc Quan- General Manager. This is a content of interview:

PV: How do you treat the waste matter produced by the manufacturing process? How many kinds of waste matter? If not treated, how does it harm to environment?

Mrs.Quan: There are 3 kinds of waste matter: solid waste, liquid waste and gasous waste. Our field of production includes aluminium laminated packaging paper and paper core. We maintain waste treatment from the source of waste, such as:

Classification of residence waste by storage container into two types: disposal waste and recycling waste.

The waste in the list of hazardous waste are identified and collected by the professional licensed units in collection of hazardous waste.

Building of a dual drainage system including storm water and domestic wastewater connected to the wastewater treatment system of Linh Trung 2 Industrial Part.

Installation of a waste paper collection system that is connected to a trash compactor.

Installation of a trash compactor to prevent discard during transportation.

If the waste is not properly treated, workers will be disadvantaged and business will be damage

Workers long term exposure to polluted gas could lead to degeneration of health and contracting of chronic diseases. The business is also at risk from potential fire hazards and resignation of workers who seeking more environmental friendly workplace.

PV: Please tell us the solution of your business in environmental protection, sustainable development? How do you invest equipment to industrial waste treament produced by manufacturing process?How about it’s affect?

Mrs.Quan: To environmental protection and sustainable development, we took “human” as the originator. The leader themselves must appreciate the importance of environmental protection in production and business activities and help the management and executives to have a thorough grasp of the problem by working in unity. Besides that, we maintain and promote the following activities:

Establish a Board of safety inspection that checks twice a week to record pictures and submission of a report of any infringements. Head of departments are then tasked with the responsibility of developing plan of actions to address such infringements.

Establish a Board of communication to that utilizes internal news-letter and news page in website as propaganda to workers and customers.

Setting up a green area, which is about 30% of the total area, to maintain green environment.

Persuade customer to accept changing from solvent ink to water-based ink.

Install compact fluorescent lamp instead of high pressure lamp.

Produce recycle laminated paper but only export to EU because the cost price is sensitive to local customer.

The implementation of the above has created a strong and lasting impression of our environmental friendly image to our customers, leading to organic growth in sales figures and profit. Workers dedication improved as they felt their health was well attended to and cared for, leading to greater harmony and unity towards achieving a common objective.

PV: Please tell me about the centre of direction in 2010 to 2015, special in environment protection, build a Green trade marks – firmly development?

Mrs.Quan: It has been an arduous task to achieve The sustainable green trademark as the organization committee’s criteria were extremely stringent. The intricacy of needing to maintain and promote environment protection in parallel with business development required great efforts and commitments..

In the period from 2010 to 2015 and beyond, we have set a direction of technology investment and production developing towards being with environmental friendly by clean, useful, recyclable or reusable products:

Replacement of diesel forklift with electric forklift to eliminate dust and exhaust pollution in the manufacturing area.

Enhancement of the building infrastructure to improve air convection in factory and extend a new factory to rearrange production centrally, reasonably, effectively.

Engagement with scientists and experts to develop processes that turns disposal to useful products.

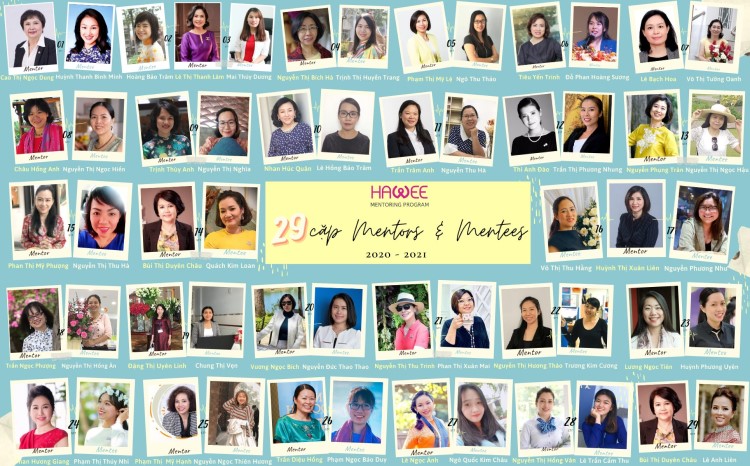

Team of Communication – New Toyo (Vietnam)

TAG: